AI Vision Platform for High-Mix Automation

Use standard RGB cameras for robust robot vision in high-mix cells. Get zero-shot 6D pose and inline inspection directly from CAD.

-

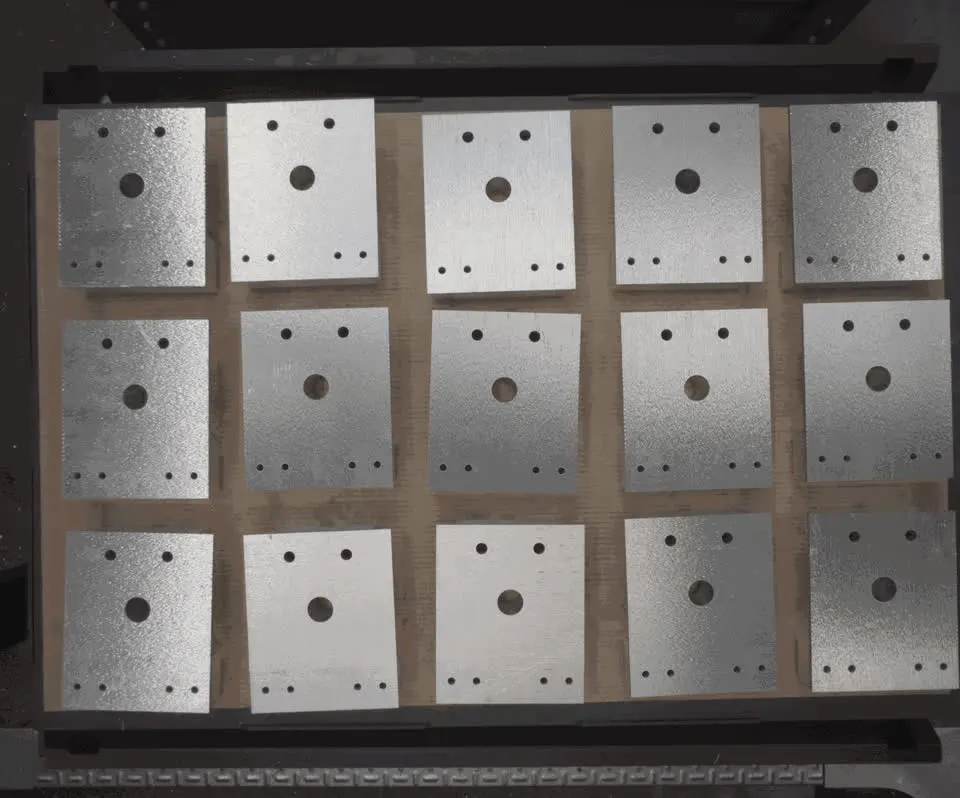

Production-proven in real cells

Used daily by OEM and integrator partners.

-

Pilot in 2-3 weeks

From first setup to production validation.

-

CAD in. Picking out.

Zero-shot for new parts. No per-part retraining.

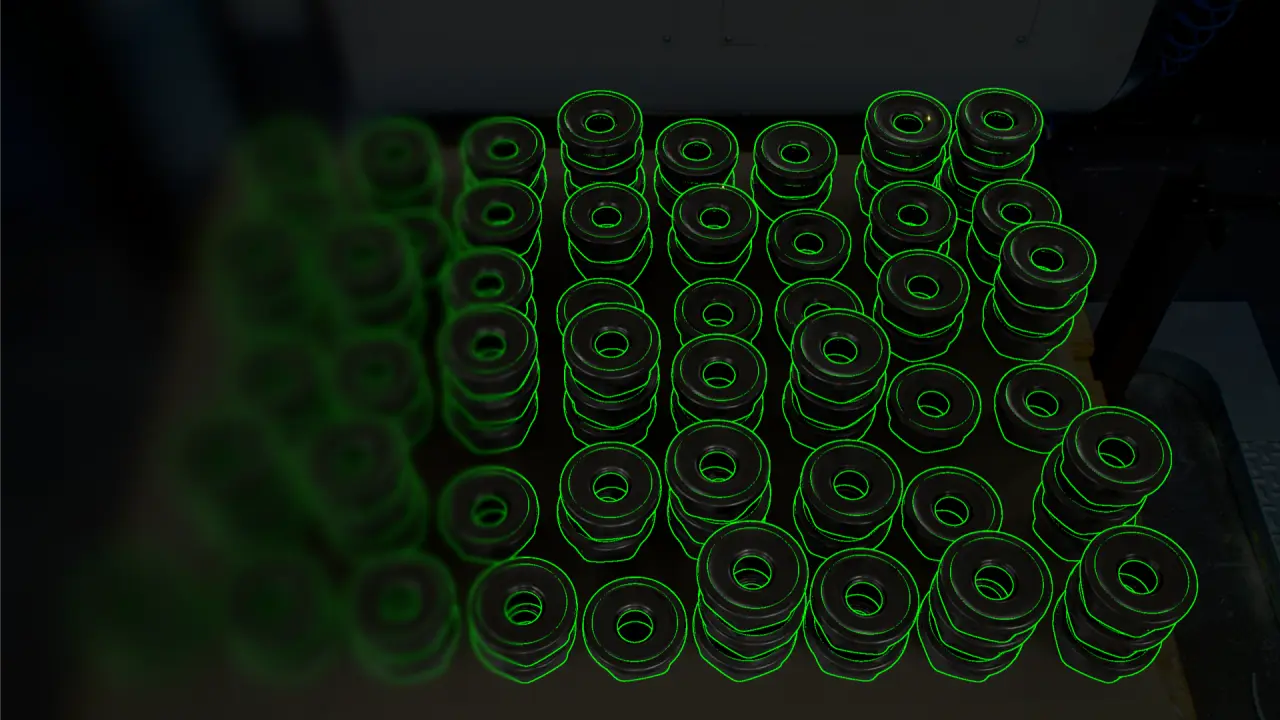

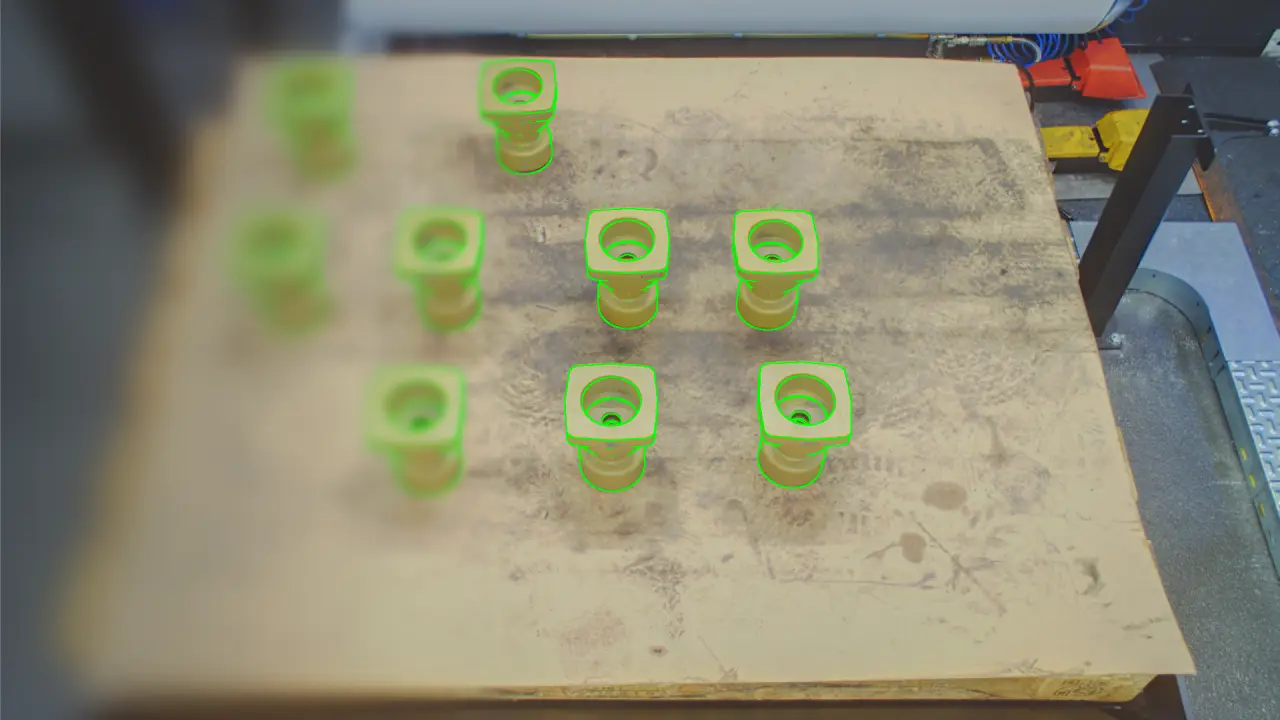

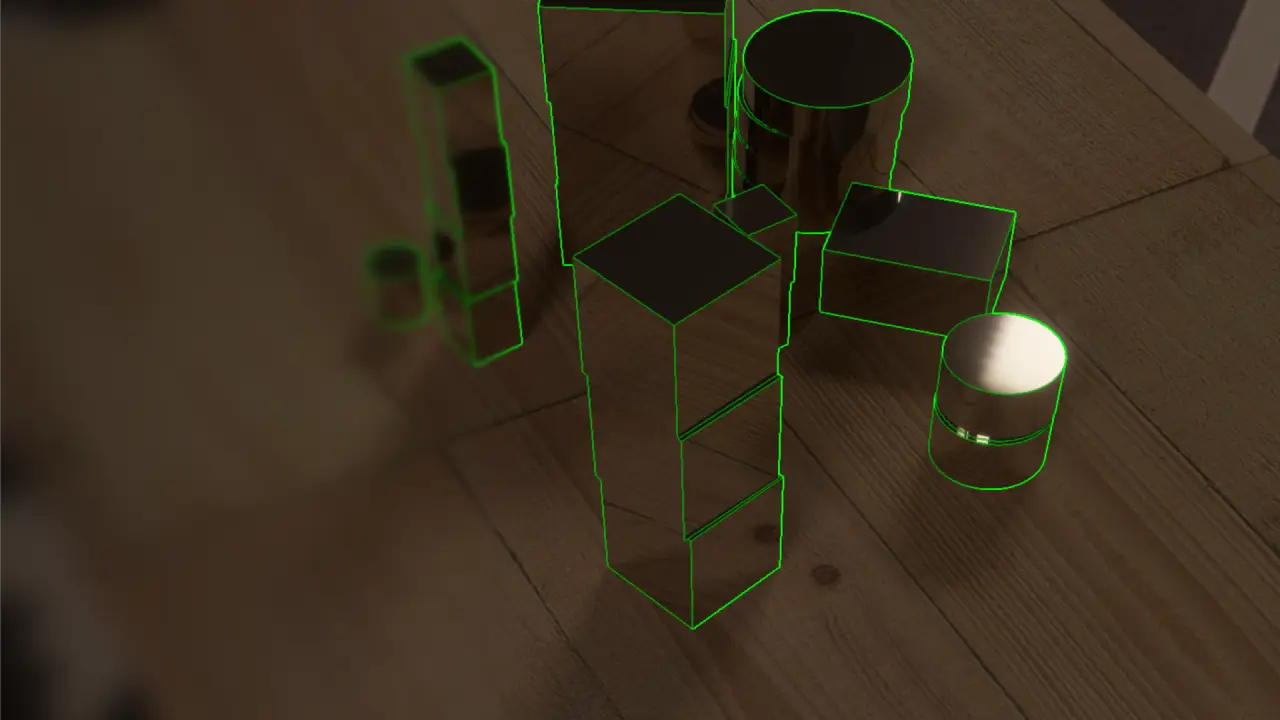

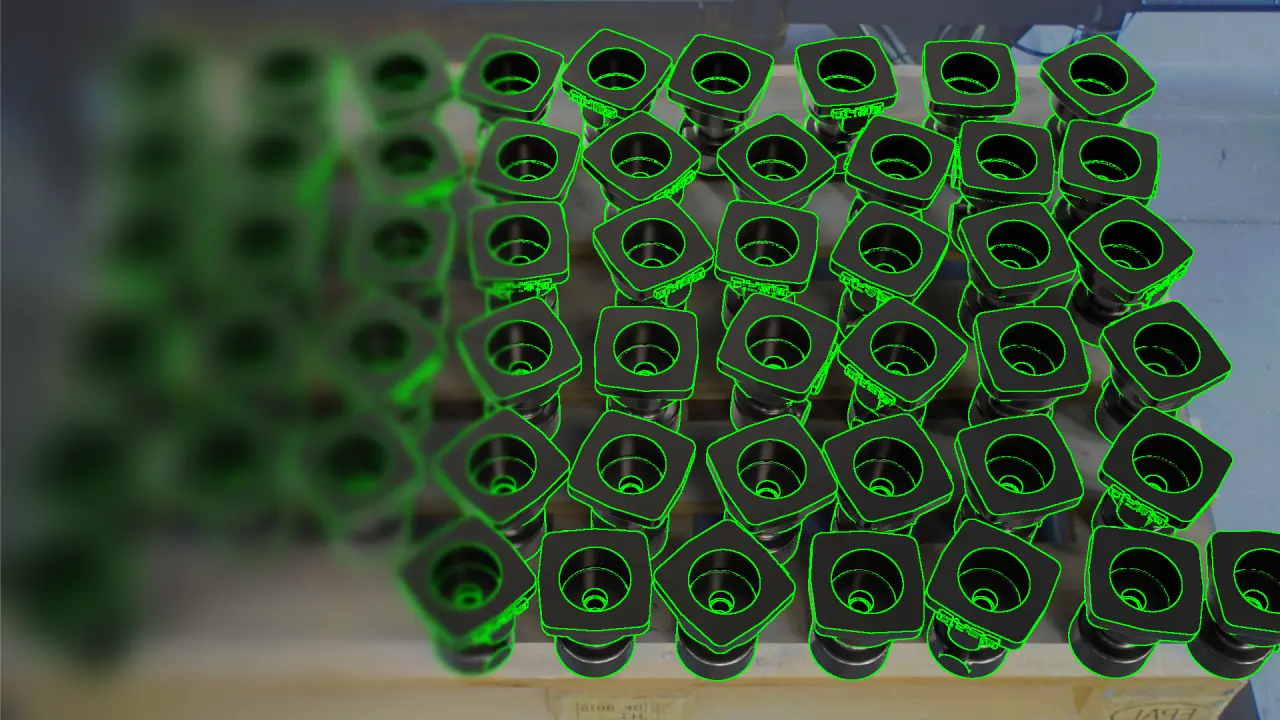

helder.ai in Action

What You Get

Easy Camera Setup

Start fast with guided calibration. Works with standard industrial cameras, independent of camera brand.

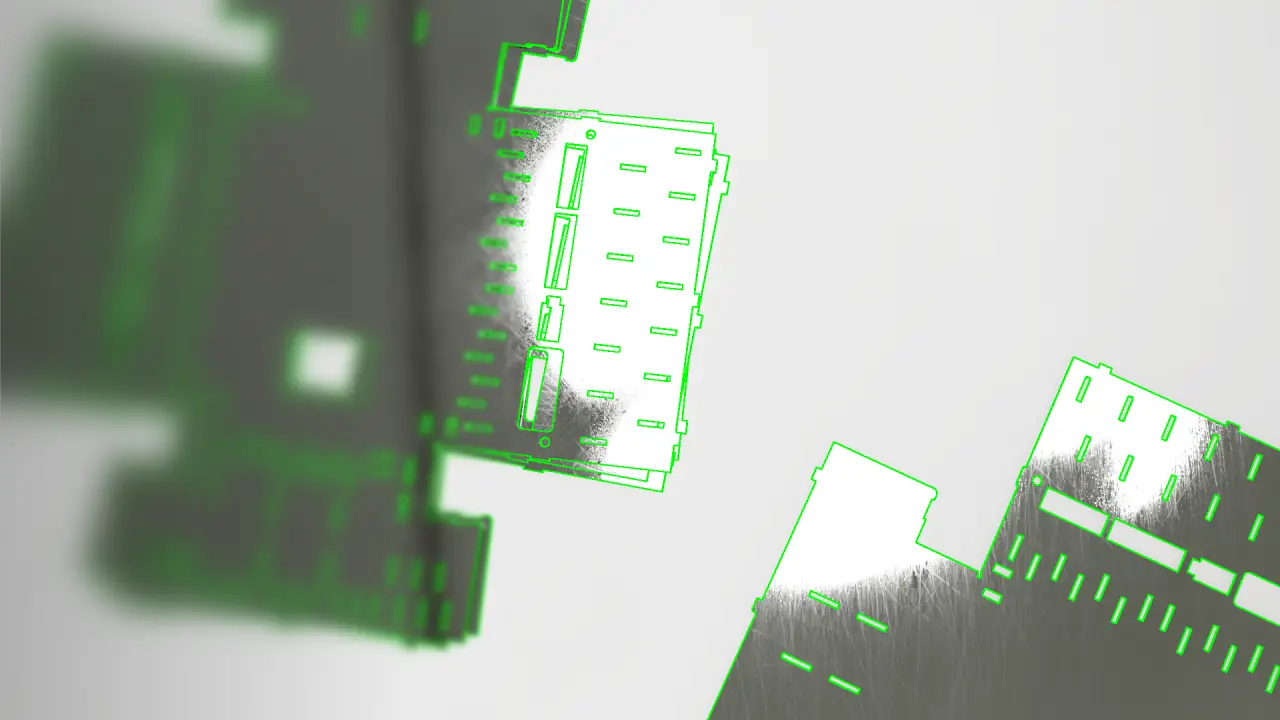

Zero-Shot 6D Pose from CAD

Find unseen parts with precise pose output for reliable robotic picking.

Inline Quality Control

Check geometry and critical features before pick, load, or place.

Built for Industrial Reality

01 / 09

From CAD to Production in 3 Steps

01

Connect

Install cameras, define the cell once, and calibrate via web UI and API.

02

Upload

Upload CAD for a new part and capture live cell images.

03

Run

Get ranked poses and inspection signals in real time via REST API.

API-First Integration

# Create the scene and upload CAD assets

scene_uid = client.post("/scene").json()["uid"]

cad_uid = client.post(

"/cad",

files={"file": open("part.ply", "rb")},

).json()["uid"]

# Send camera images and request 6D poses

client.post(

f"/scene/{scene_uid}/image",

data={"positioned_camera_uid": camera_uid},

files={"file": ("image.jpg", image_data)},

)

response = client.post(

f"/scene/{scene_uid}/find-objects",

json={

"cad_uid": cad_uid,

"picking_strategy": {"type": "HEIGHT"},

},

)

poses = response.json()["objects"]FAQ

How fast can we go live?

Most teams run a first production pilot in 2-3 weeks. Rollout usually starts with a one-time camera setup and calibration, then part changes happen digitally via CAD upload.

Do we need 3D scanners or custom trays?

No. Helder is built for standard industrial RGB cameras on commodity GPU hardware, so you avoid high-cost 3D sensors and rigid tray-based workflows.

Will this fit our current robotics stack?

Yes. Helder is API-first and brand-agnostic. We integrate via REST with PLCs, robot controllers, and cell orchestration software without replacing your current stack.

What do we need for a new part?

Start with the CAD model and at least two representative camera images. Helder returns 6D poses and inspection signals in zero-shot mode, without per-part retraining.

Is the technology production-proven?

Yes. Helder runs at TRL 9 in daily production with active systems deployed through OEM partners and end customers.

Ready for Your First Pilot?

Share your cell setup and part mix. We will map a concrete rollout plan with your team.

Schedule a Technical Call